Integration of Genetic Algorithm and Hedge Algebras in controlling mechanical machining robots

Author affiliations

DOI:

https://doi.org/10.15625/0866-7136/21000Keywords:

Genetic Algorithms, Hedge Algebras, control, mechanical machining robot, physical value domainAbstract

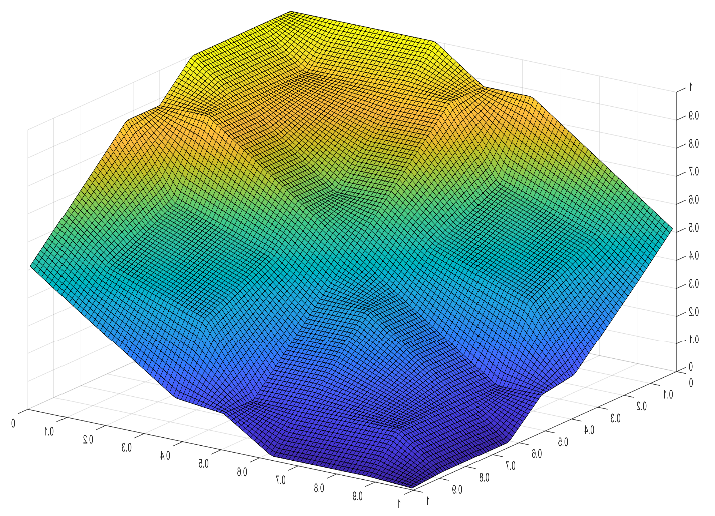

Robot applications in mechanical processing have become popular. The critical issue when applying robots in mechanical processing is ensuring accuracy. Usually, robot control is based on dynamic models. This method has difficulty accurately determining the system's dynamic model because the robot has a complex structure. Besides, dynamic factors such as cutting force, friction force and machining conditions constantly change. Robot control based on Hedge Algebras gives excellent and reliable results. The critical factors that determine the quality and reliability of the Hedge Algebra controller are the Control Law, the method of Denormalization, and the determination of the Physical Value Domain. The construction of the Control Law and Denormalization is based on expert knowledge. Determining the physical value domain is problematic because it requires many experiments. This article introduces the method of applying genetic algorithms to find the appropriate physical value domain for the controller based on Hedge Algebras. The article presents a robot controller based on Hedge Algebras to do this. Numerical experiments with a mechanical machining robot verify the results.

Downloads

References

I. Iglesias, M. A. Sebastián, and J. E. Ares. Overview of the state of robotic machining: Current situation and future potential. Procedia Engineering, 132, (2015), pp. 911–917.

M. Petko, G. Karpiel, K. Gac, G. G´óra, K. Kobus, and J. Ochoński. Trajectory tracking controller of the hybrid robot for milling. Mechatronics, 37, (2016), pp. 100–111.

G. Gołda and A. Kampa. Modelling of cutting force and robot load during machining. Advanced Materials Research, 1036, (2014), pp. 715–720.

COMET, EU. P7-project: Plug-and-produce COmponents and METhods for adaptive control of industrial robots enabling cost effective, high precision manufacturing in factories of the future, (2011).

W. Ji and L. Wang. Industrial robotic machining: a review. The International Journal of Advanced Manufacturing Technology, 103, (2019), pp. 1239–1255.

A. M. Abdul-Sadah, K. M. H. Raheem, and M. M. S. Altufaili. A fuzzy logic controller for a three links robotic manipulator. In AIP Conference Proceedings, AIP Publishing, (2022).

N. V. Toan and P. B. Khoi. Fuzzy-based-admittance controller for safe natural human–robot interaction. Advanced Robotics, 33, (2019), pp. 815–823.

P. B. Khoi and N. V. Toan. Application of fuzzy logic for controlling mechanism of relative manipulation robot (MRM robot). Vietnam Journal of Science and Technology, 54, (2016), pp. 386–401.

P. B. Khoi and H. Nguyen Xuan. Fuzzy logic-based controller for bipedal robot. Applied Sciences, 11, (2021).

K. B. Phan, H. T. Ha, and S. V. Hoang. Eliminating the effect of uncertainties of cutting forces by fuzzy controller for robots in milling process. Applied Sciences, 10, (2020).

N. V. Toan and P. B. Khoi. A control solution for closed-form mechanisms of relative manipulation based on fuzzy approach. International Journal of Advanced Robotic Systems, 16, (2019).

C. W. de Silva. Applications of fuzzy logic in the control of robotic manipulators. Fuzzy Sets and Systems, 70, (1995), pp. 223–234.

P. B. Khoi. Application of fuzzy logic in the robot control for mechanical processing. Vietnam Journal of Science and Technology, 61, (2023), pp. 531–569.

P. B. Khoi and N. V. Toan. Hedge-algebras-based controller for mechanisms of relative manipulation. International Journal of Precision Engineering and Manufacturing, 19, (2018), pp. 377–385.

T. Nguyen Van, S.-Y. Yi, and P. Bui Khoi. Hedge algebras-based admittance controller for safe natural human–robot interaction. Advanced Robotics, 34, (2020), pp. 1546–1558.

N.-V. Toan, P.-B. Khoi, and S.-Y. Yi. A MLP-Hedge-Algebras admittance controller for physical human–robot interaction. Applied Sciences, 11, (2021).

N. V. Toan, M. Do Hoang, P. B. Khoi, and S.-Y. Yi. The human-following strategy for mobile robots in mixed environments. Robotics and Autonomous Systems, 160, (2023).

N. Van Toan, P. B. Khoi, and S.-Y. Yi. A single 2-D LiDAR extrinsic calibration for autonomous mobile robots. IEEE Transactions on Instrumentation and Measurement, 72, (2023), pp. 1–9.

N. D. Anh, H.-L. Bui, N.-L. Vu, and D.-T. Tran. Application of hedge algebra-based fuzzy controller to active control of a structure against earthquake: HA-based fuzzy controller to structural active control. Structural Control and Health Monitoring, 20, (2011), pp. 483–495.

D. Vukadinović, M. Bašić, C. H. Nguyen, N. L. Vu, and T. D. Nguyen. Hedge-algebrabased voltage controller for a self-excited induction generator. Control Engineering Practice, 30, (2014), pp. 78–90.

Downloads

Published

How to Cite

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.