Numerical simulation of springback and twisting of stamped thin U-shaped copper alloy sheets with a change of the blank alignment

Author affiliations

DOI:

https://doi.org/10.15625/0866-7136/17662Keywords:

copper alloys, thin sheet metal, deep drawing, springback, twistingAbstract

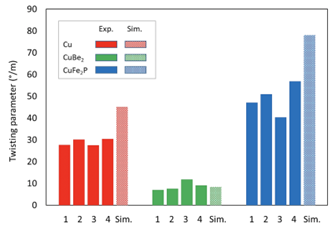

An experimental database of springback and twisting of U-shaped elongated structures is available from a previous study. The materials are copper alloys: pure Cu, CuBe2, and CuFe2P, provided in thin sheets of thickness around 0.1 mm. After deep-drawing of rectangular blanks, which can be aligned with the tools or slightly misaligned, and tool withdrawal, the U-shaped structure exhibits an opening of the section (2D springback) and twisting (3D springback). Characteristic features of the deformed geometry are significantly different for the three alloys. This study is directed to understand the origin of that difference with a numerical simulation of the process. The mechanical behaviour of the materials was investigated in tension and hydraulic bulge test, out of comparison’s sake and to derive the hardening law over a strain range representative of the process. Finite element simulations are performed using the von Mises criterion coupled with isotropic hardening, to compare the predicted forming load and springback parameters with experimental values.

Downloads

References

Copper and Copper Alloys. General information - introduction to copper and its alloys. Accessed Nov. 09, 2022.

G. X. Ha, M. G. Oliveira, A. Andrade-Campos, P. Y. Manach, and S. Thuillier. Prediction of coupled 2D and 3D effects in springback of copper alloys after deep drawing. International Journal of Material Forming, 14, (2021), pp. 1171–1187.

H. B. Mullan. Improved prediction of springback on final formed components. Journal of Materials Processing Technology, 153-154, (2004), pp. 464–471.

C. Gomes, O. Onipede, and M. Lovell. Investigation of springback in high strength anisotropic steels. Journal of Materials Processing Technology, 159, (2005), pp. 91–98.

V. Esat, H. Darendeliler, and M. I. Gokler. Finite element analysis of springback in bending of aluminium sheets. Materials & Design, 23, (2002), pp. 223–229.

P. Chen and M. Koc¸. Simulation of springback variation in forming of advanced high strength steels. Journal of Materials Processing Technology, 190, (2007), pp. 189–198.

H.-L. Dai, H.-J. Jiang, T. Dai, W.-L. Xu, and A.-H. Luo. Investigation on the influence of damage to springback of U-shape HSLA steel plates. Journal of Alloys and Compounds, 708, (2017), pp. 575–586.

M. Dezelak, A. Stepisnik, and I. Pahole. Evaluation of twist springback prediction after an AHSS forming process. International Journal of Simulation Modelling, 13, (2014), pp. 171–182.

H. Li, G. Sun, G. Li, Z. Gong, D. Liu, and Q. Li. On twist springback in advanced high-strength steels. Materials & Design, 32, (2011), pp. 3272–3279.

M. Takamura, M. Sakata, A. Fukui, T. Hama, Y. Miyoshi, H. Sunaga, A. Makinouchi, and M. Asakawa. Investigation of twist in curved hat channel products by elastic-plastic finite element analysis. International Journal of Material Forming, 3, (2010), pp. 131–134.

C. H. Pham, S. Thuillier, and P. Y. Manach. Twisting analysis of ultra-thin metallic sheets. Journal of Materials Processing Technology, 214, (2014), pp. 844–855.

C. H. Pham, S. Thuillier, and P.-Y. Manach. 2D springback and twisting of ultrathin stainless steel U-shaped parts. steel research international, 86, (2015), pp. 861–868.

A. Ishiwatari, H. Kano, J. Hiramoto, and T. Inazumi. Improvement on CAE model for accurate torsional springback prediction in high strength steel part forming. Key Engineering Materials, 504-506, (2012), pp. 437–442.

S. Thuillier, C. H. Pham, and P. Y. Manach. 2D springback and twisting after drawing of copper alloy sheets. Journal of Physics: Conference Series, 1063, (2018).

C. H. Pham, S. Thuillier, and P. Y. Manach. Twisting of sheet metals. In AIP Conference Proceedings, AIP, Vol. 1567, (2013), pp. 422–427.

F. Adzima, T. Balan, P. Y. Manach, N. Bonnet, and L. Tabourot. Crystal plasticity and phenomenological approaches for the simulation of deformation behavior in thin copper alloy sheets. International Journal of Plasticity, 94, (2017), pp. 171–191.

S. T. C. H. Pham and P.-Y. Manach. Experimental investigation and numerical prediction of twisting. In Proceedings of IDDRG 2014 Conference, Paris, France, (2014).

C3D8R and F3D8R. http://web.mit.edu/calculix v2.7/CalculiX/ccx 2.7/doc/ccx/node27.html. Accessed Oct. 09, 2022.

J. S. Langer, E. Bouchbinder, and T. Lookman. Thermodynamic theory of dislocation-mediated plasticity. Acta Materialia, 58, (2010), pp. 3718–3732.

K. C. Le, Y. Piao, and T. M. Tran. Thermodynamic dislocation theory: Torsion of bars. Physical Review E, 98, (2018).

K. C. Le and T. M. Tran. Thermodynamic dislocation theory: Bauschinger effect. Physical Review E, 97, (2018).

Downloads

Published

How to Cite

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.