Experimental studying the effect of water temperature on friction properties of marine propeller sliding bearing

Author affiliations

DOI:

https://doi.org/10.15625/0866-7136/16507Keywords:

tribology, friction coefficient, marine sliding bearing, polymer materialAbstract

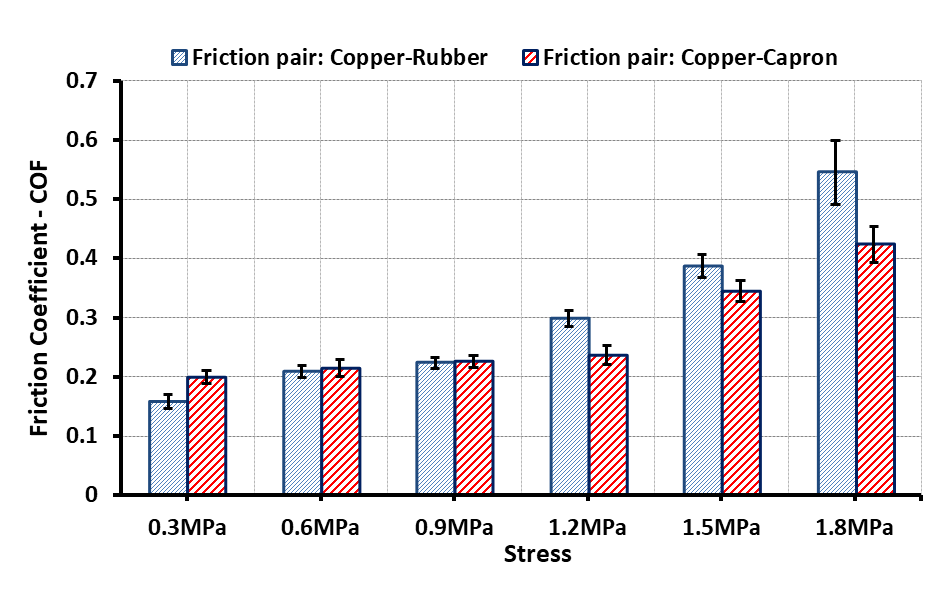

This paper presents the effect of water’s temperature on the friction properties of materials used in marine propeller sliding bearing. Copper-Rubber and Copper-Capron, two common pairs of material in the shaft water-lubricated polymer bearing were chosen to conduct experiments with the pin-on-disc model. Various conditions including water temperature, stress, and sliding velocity were examined, their results showed that in the range 30 °C to 100 °C of water temperature, the frictional coefficient of both friction pairs were unchanged under the small stress and low sliding velocity (0.3 MPa and 0.9 m/s). While in the case of stress and sliding velocity were both high (0.6 MPa and 1.5 m/s), it increased significantly in a certain transition temperature range. This temperature range of the pair Copper-Rubber and Copper-Capron is 50 °C to 60 °C and 80 °C to 90 °C, respectively. The experiment’s results also pointed out that in these transition temperature ranges, the friction coefficient of two pairs was slightly influenced by the change in sliding velocity, whereas the stress change has an important impact on its values. Nonetheless, when the water temperature was below the transition range, the effect of the stress change on the friction coefficient was not significant. Thus, high water temperature is the main reason for the friction coefficient’s increase rather than the increase of the stress. This work is expected to broaden the understanding of the friction behavior of the water-lubricated polymer bearing.

Downloads

References

Y. Bai and W.-L. Jin. Marine structural design. Elsevier, (2016).

J. Carlton. Marine propellers and propulsion. Butterworth-Heinemann, (2018).

L. Roldo, I. Komar, and N. Vuli´c. Design and materials selection for environmentally friendly ship propulsion system. Strojniˇski vestnik – Journal of Mechanical Engineering, 59, (2013), pp. 25–31.

W. Litwin. Marine propeller shaft bearings under low-speed conditions: water vs. oil lubrication. Tribology Transactions, 62, (2019), pp. 839–849.

R. L. Orndorff. Water lubricated rubber bearings, history and new developments. Naval Engineers Journal, 97, (1985), pp. 39–52.

W. Litwin. Water-lubricated bearings of ship propeller shafts - problems, experimental tests and theoretical investigations. Polish Maritime Research, 16, (2009).

W. Litwin. Influence of main design parameters of ship propeller shaft waterlubricated bearings on their properties. Polish Maritime Research, 17, (2010), pp. 39–45.

G. Vizentin, G. Vukelic, L. Murawski, N. Recho, and J. Orovic. Marine propulsion system failures—A review. Journal of Marine Science and Engineering, 8, (2020).

B. Primorac and J. Parunov. Review of statistical data on ship accidents. In Maritime Technology and Engineering III, CRC Press, (2016), pp. 809–814,

A. Ford. New composite seal and bearing technology for better performance. Wartsila Tech J, 1, (2012), pp. 34–39.

Y.-Q. Wang, X.-J. Shi, and L.-J. Zhang. Experimental and numerical study on waterlubricated rubber bearings. Industrial Lubrication and Tribology, 66, (2014), pp. 282–288.

G. Gao, Z. Yin, D. Jiang, and X. Zhang. Numerical analysis of plain journal bearing under hydrodynamic lubrication by water. Tribology International, 75, (2014), pp. 31–38.

G. Cui, Q. Bi, S. Zhu, J. Yang, and W. Liu. Tribological properties of bronze–graphite composites under sea water condition. Tribology International, 53, (2012), pp. 76–86.

R. F. King and D. Tabor. The effect of temperature on the mechanical properties and the friction of plastics. Proceedings of the Physical Society. Section B, 66, (9), (1953).

A. Jean-Fulcrand, M. A. Masen, T. Bremner, and J. S. S. Wong. Effect of temperature on tribological performance of polyetheretherketone-polybenzimidazole blend. Tribology International, 129, (2019), pp. 5–15.

F. Zheng, M. Lv, Q.Wang, and T.Wang. Effect of temperature on friction and wear behaviors of polyimide (PI)-based solid–liquid lubricating materials. Polymers for Advanced Technologies, 26, (8), (2015), pp. 988–993.

W. Litwin and C. Dymarski. Experimental research on water-lubricated marine stern tube bearings in conditions of improper lubrication and cooling causing rapid bush wear. Tribology International, 95, (2016), pp. 449–455.

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.