Tuning acoustic performance of multi-chamber hybrid mufflers

Author affiliations

DOI:

https://doi.org/10.15625/0866-7136/14904Keywords:

exhaust muffler, low frequency, sound transmission loss, partition, micro-perforated tubeAbstract

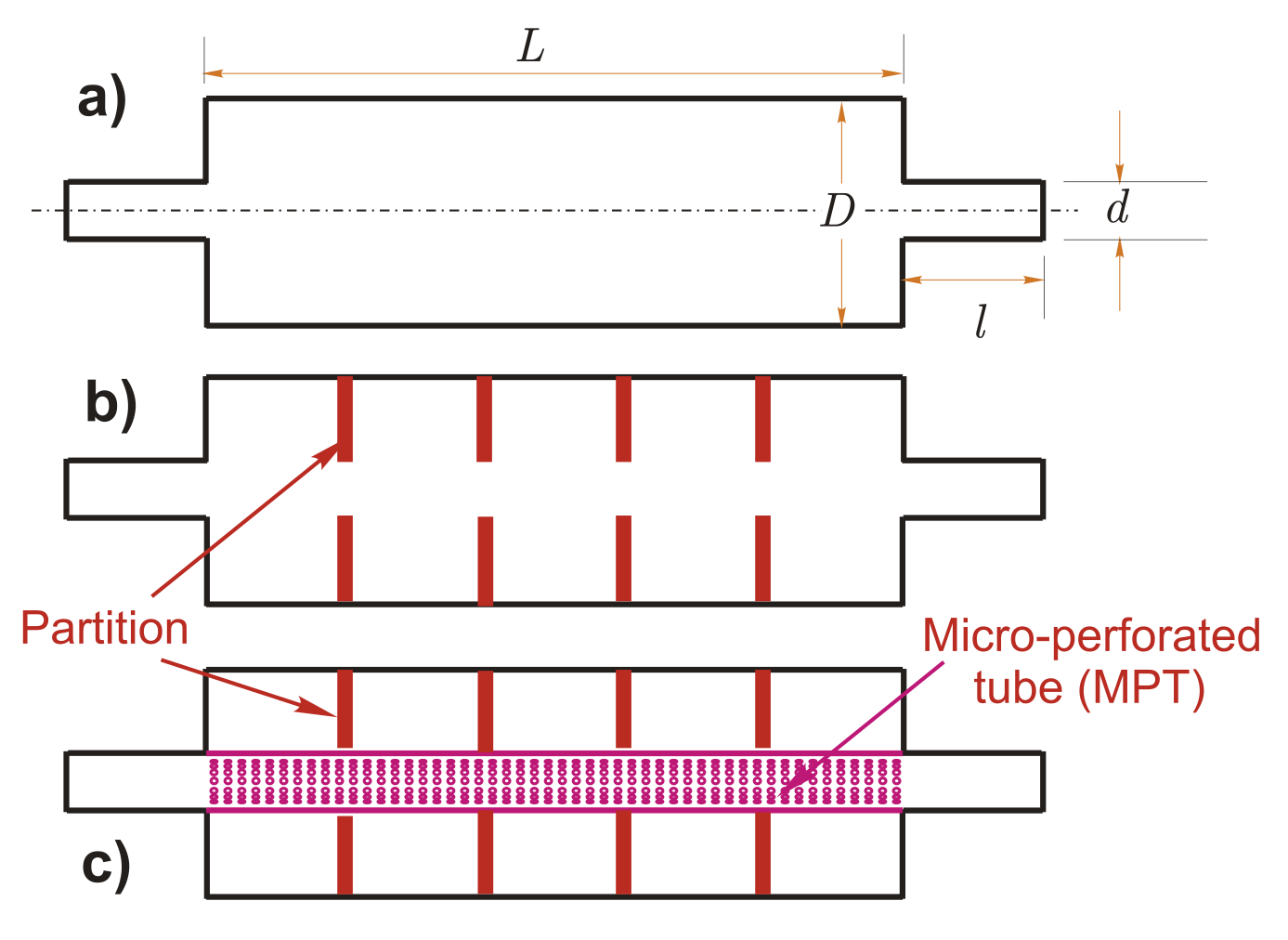

In this paper, we investigate the functional acoustic performance of multi-chamber mufflers using a numerical approach. The wave propagation governing in expansion chamber domains is first introduced and solved by the finite element method. Our numerical results of selected muffler configurations are compared with the reference predictions model and experiments in order to validate the present procedure. Then, the influence of the geometry characteristics of typical and hybrid configurations of multi-chambered mufflers (number of sub-chambers, micro-perforated tube structure) on their sound transmission loss is studied. The obtained results indicate that the structure of the considered muffler has a strong effect on their acoustical performance, and the location and the high level of resonances of the sound transmission loss behavior are strongly related to the number of sub-chambers as well as micro-perforated tube characteristics. By tuning geometrical parameters (e.g., having a small perforation ratio), we enable to design mufflers having a higher sound transmission loss (up to 110 dB) at low frequencies (~ 195 Hz) but a constraint space (e.g., acoustic chamber length of 300 mm).

Downloads

References

F. Jacobsen. Propagation of sound waves in ducts. Lecture note - Advanced Acoustics, Acoustic Technology, Orsted DTU, (2005).

M. Munal. Acoustics of Ducts and Muffers. New York: Wiley-Interscience, (1987).

P. C. Mishra, S. K. Kar, H. Mishra, and A. Gupta. Modeling for combined effect of muffler geometry modification and blended fuel use on exhaust performance of a four stroke engine: A computational fluid dynamics approach. Applied Thermal Engineering, 108, (2016), pp. 1105–1118.

A. Selamet and Z. Ji. Acoustic attenuation performance of circular expansion chambers with offset inlet/outlet: I. analytical approach. Journal of Sound and Vibration, 213, (4), (1998), pp. 601–617.

A. Selamet and P. Radavich. The effect of length on the acoustic attenuation performance of concentric expansion chambers: an analytical, computational and experimental investigation. Journal of Sound and Vibration, 201, (4), (1997), pp. 407–426.

A. Selamet and Z. Ji. Acoustic attenuation performance of circular expansion chambers with single-inlet and double-outlet. Journal of sound and vibration, 229, (1), (2000), pp. 3–19.

A. Elsayed, C. Bastien, S. Jones, J. Christensen, H. Medina, and H. Kassem. Investigation of baffle configuration effect on the performance of exhaust mufflers. Case Studies in Thermal Engineering, 10, (2017), pp. 86–94.

A. Sahasrabudhe, S. A. Ramu, and M. Munjal. Matrix condensation and transfer matrix techniques in the 3-d analysis of expansion chamber mufflers. Journal of Sound and Vibration, 147, (3), (1991), pp. 371–394.

A. Craggs. A finite element method for damped acoustic systems: an application to evaluate the performance of reactive mufflers. Journal of Sound and Vibration, 48, (3), (1976), pp. 377–392.

J. Zhenlin, M. Qiang, and Z. Zhihua. Application of the boundary element method to predicting acoustic performance of expansion chamber mufflers with mean flow. Journal of Sound and Vibration, 173, (1), (1994), pp. 57–71.

C. Cheng, A. Seybert, and T.Wu. A multidomain boundary element solution for silencer and muffler performance prediction. Journal of Sound and Vibration, 151, (1), (1991), pp. 119–129.

Z. Tao and A. Seybert. A review of current techniques for measuring muffler transmission loss. SAE transactions, (2003), pp. 2096–2100.

T. Lung and A. Doige. A time-averaging transient testing method for acoustic properties of piping systems and mufflers with flow. The Journal of the Acoustical Society of America, 73, (3), (1983), pp. 867–876.

M. Munjal and A. Doige. Theory of a two source-location method for direct experimental evaluation of the four-pole parameters of an aeroacoustic element. Journal of Sound and Vibration, 141, (2), (1990), pp. 323–333.

L. Eriksson. Effect of inlet/outlet locations on higher order modes in silencers. The Journal of the Acoustical Society of America, 72, (4), (1982), pp. 1208–1211.

L. Eriksson. Higher order mode effects in circular ducts and expansion chambers. The Journal of the Acoustical Society of America, 68, (2), (1980), pp. 545–550.

A. Antebas, A. Pedrosa, F. Denia, and F. Fuenmayor. Acoustic behaviour of circular chamber mufflers with single inlet and double opposite outlet. In 19th International Congress on Acoustics, Madrid, (2007).

D.-Y. Maa. Potential of microperforated panel absorber. The Journal of the Acoustical Society of America, 104, (5), (1998), pp. 2861–2866.

M. Abom and S. Allam. Dissipative silencers based on micro-perforated plates. Report 0148-7191, SAE Technical Paper, (2013).

S. Allam and M. Åbom. A new type of muffler based on microperforated tubes. Journal of vibration and acoustics, 133, (3), (2011).

M. Q. Wu. Micro-perforated panels for duct silencing. Noise Control Engineering Journal, 45, (2), (1997), pp. 69–77.

X. Yu, L. Cheng, and X. You. Hybrid silencers with micro-perforated panels and internal partitions. The Journal of the Acoustical Society of America, 137, (2), (2015), pp. 951–962.

M. Rahman, T. Sharmin, A. Hassan, and M. Al Nur. Design and construction of a muffler for engine exhaust noise reduction. In Proceedings of the International Conference on Mechanical Engineering ICME, (2005), pp. 28–30.

D. Neihguk and S. Fulkar. Acoustic analysis of a tractor muffler. SAE Technical Paper Series, (2017).

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Funding data

-

National Foundation for Science and Technology Development

Grant numbers 107.01-2019.316