Research on a flow-mode magneto-rheological impact damper with stroke-activated capability

Author affiliations

DOI:

https://doi.org/10.15625/0866-7136/22318Keywords:

adaptive, flow-mode, impact damper, magneto-rheological, stroke-activatedAbstract

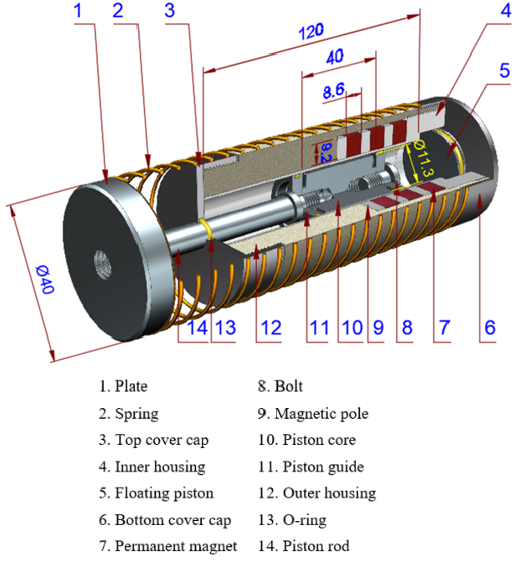

It is widely recognized that impact is an intricate problem that has challenged scientific scholars for many years. Impacts, such as those occurring in high-speed aircraft landings, vehicle accidents, or machine tool operations, pose substantial hazards to human health and safety, as well as cause damage to the structural durability, integrity and sustainability of various facilities. This paper researches a flow-mode magneto-rheological (MR) impact damper (ID) to reduce the effects of shocks and vibrations during sudden impacts. By applying a magnetic field to the magneto-rheological fluid (MRF) within the damper, the damping properties can be adjusted in real-time. The traditional approaches typically use electric coils to generate the required magnetic field, leading to increased complexity and high costs in structure and control systems. To address this limitation, we replace the coils with multiple permanent magnets distributed along the linear displacement of the damper, enabling the generation of a progressive damping force. Therefore, in addition to a more streamlined design, the new configuration equips the MRID with a stroke-activated capability that aids in creating a soft-landing effect, thereby minimizing harm during collisions. To improve the operational efficiency, performance criteria of the damper, including damping force in off and activated states, dynamic range and installation volume, are considered in a design optimization procedure. Optimal solutions for the proposed MRID are simulated using the finite element method (FEM), followed by a detailed design phase. Subsequent analyses and discussions are conducted to provide guidance for future development.

Downloads

References

[1] Q. H. Nguyen, S. B. Choi, and J. K. Woo. Optimal design of magnetorheological fluid-based dampers for front-loaded washing machines. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 228, (2013), pp. 294–306. https://doi.org/10.1177/0954406213485908.

[2] S. Jin, L. Deng, J. Yang, S. Sun, D. Ning, Z. Li, H. Du, and W. H. Li. A smart passive MR damper with a hybrid powering system for impact mitigation: An experimental study. Journal of Intelligent Material Systems and Structures, 32, (2021), pp. 1452–1461. https://doi.org/10.1177/1045389x20988085.

[3] Y.-T. Choi, R. Robinson, W. Hu, N. M. Wereley, T. S. Birchette, A. O. Bolukbasi, and J. Woodhouse. Analysis and control of a magnetorheological landing gear system for a helicopter. Journal of the American Helicopter Society, 61, (2016), pp. 1–8. https://doi.org/10.4050/jahs.61.032006.

[4] Z. Feng, Z. Chen, and X. Xing. An adaptive shock mitigation control method for helicopter seat system with magnetorheological energy absorbers. Journal of Intelligent Material Systems and Structures, 33, (2021), pp. 987–1001. https://doi.org/10.1177/1045389x211038708.

[5] M. Wang, Z. Chen, and N. M. Wereley. Adaptive magnetorheological energy absorber control method for drop-induced shock mitigation. Journal of Intelligent Material Systems and Structures, 32, (2020), pp. 449–461. https://doi.org/10.1177/1045389x20957100.

[6] T. Maeda, M. Otsuki, and T. Hashimoto. Protection against overturning of a lunar-planetary lander using a controlled landing gear. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 233, (2017), pp. 438–456. https://doi.org/10.1177/0954410017742931.

[7] J. Zheng, J. Zhao, L. Wang, Z. Li, W. Dong, and E. Shiju. Optimal control for soft-landing in elevator emergency crash using multiple magnetorheological shock absorbers. Journal of Intelligent Material Systems and Structures, 33, (2022), pp. 2454–2469. https://doi.org/10.1177/1045389x221085646.

[8] M. Jiang, X. Rui, W. Zhu, F. Yang, and Y. Zhang. Design and control of helicopter main reducer vibration isolation platform with magnetorheological dampers. International Journal of Mechanics and Materials in Design, 17, (2021), pp. 345–366. https://doi.org/10.1007/s10999-021-09529-x.

[9] Y. T. Choi, N. M. Wereley, and G. J. Hiemenz. Three-axis vibration isolation of a full-scale magnetorheological seat suspension. Micromachines, 15, (2024). https://doi.org/10.3390/mi15121417.

[10] C. W. de Silva. Vibration: fundamentals and practice. CRC Press, (1999). https://doi.org/10.1201/noe0849318085.

[11] R. C. Dorf and R. H. Bishop. Modern control systems. Pearson Education Inc., (2011).

[12] J. D. Carlson, D. M. Catanzarite, and K. A. St. Clair. Commercial magneto-rheological fluid devices. International Journal of Modern Physics B, 10, (1996), pp. 2857–2865. https://doi.org/10.1142/s0217979296001306.

[13] ANSYS Inc. DesignXplorer user’s guide. Canonsburg, PA, (2021).

[14] Q.-D. Bui, L.-V. Hoang, H.-Q. Nguyen, and Q. H. Nguyen. Design and experimental evaluation of a novel flow-mode magnetorheological damper without accumulator. Journal of Intelligent Material Systems and Structures, 35, (2024), pp. 1291–1303. https://doi.org/10.1177/1045389x241256094.

[15] H.-Q. Nguyen, Q. H. Nguyen, Q.-D. Bui, and D.-N. Nguyen. Optimal design of a magneto-rheological damper for above-knee prosthetic leg. In Proceedings of the International Conference on Sustainable Energy Technologies (ICSET 2023), Green Energy and Technology, Springer Nature Singapore, (2024), pp. 369–378. https://doi.org/10.1007/978-981-97-1868-9 38.

[16] L. B. Nguyen, C. H. Thai, N. T. Dang, and H. Nguyen-Xuan. Transient analysis of laminated composite plates using NURBS-based isogeometric analysis. Vietnam Journal of Mechanics, 36, (2014), pp. 267–281. https://doi.org/10.15625/0866-7136/36/4/4129.

[17] T. Le-Duc, Q.-H. Nguyen, and H. Nguyen-Xuan. Balancing composite motion optimization. Information Sciences, 520, (2020), pp. 250–270. https://doi.org/10.1016/j.ins.2020.02.013.

Downloads

Published

How to Cite

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Funding data

-

National Foundation for Science and Technology Development

Grant numbers 107.03-2023.86