Residual stress and deformation of welded T-joint between low carbon steel and stainless steel

Author affiliations

DOI:

https://doi.org/10.15625/0866-7136/21199Keywords:

dissimilar materials, double-sided welding, residual stress, T-joint, welding deformationAbstract

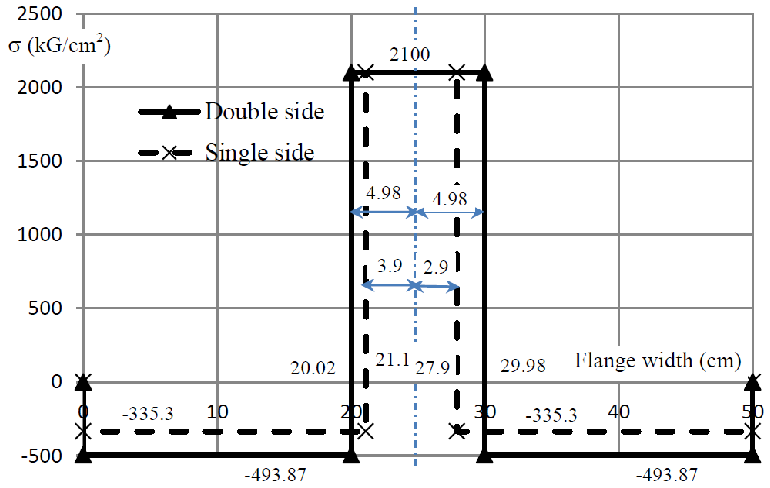

The welded structures between carbon steel and stainless steel are widely used in many sectors such as pedestrian bridges, food industry, chemical industry, petroleum, and thermal power plants, … These composite structures take advantages of each material for different parts of structure. In the welded structures between carbon steel and stainless steel, the structure is made by T-joint that is the most common. The calculation of residual stress and welding strain of the T-joint between low-carbon and stainless steel materials is the basis to evaluate the working ability of this structure. In this study, the residual stress and welding deformation of the T-joint are determined by the imaginary force method. The double-sided weld of T-joint between low carbon steel and stainless steel is welded simultaneously by MIG welding process. The obtained results of residual stress and welding deformation in this case are compared with the case of single-sided weld so that we can find the difference between residual stress and welding deformation in two cases.

Downloads

References

[1] W. Chuaiphan, C. A. Somrerk, S. Niltawach, and B. Sornil. Dissimilar welding between AISI 304 stainless steel and AISI 1020 carbon steel plates. Applied Mechanics and Materials, 268, (2013), pp. 283–290. https://doi.org/10.4028/www.scientific.net/AMM.268-270.283.

[2] V. Chauhan and R. S. Jadoun. Parametric optimization of MIG welding for stainless steel (SS-304) and low carbon steel using Taguchi design method. International Journal of Recent Scientific Research, 6, (2), (2015), pp. 2662–2666.

[3] E. Ranjbarnodeh, M. Pouranvari, and M. Farajpour. Finite-element minimization of the welding distortion of dissimilar joints of carbon steel and stainless steel. Materials and Technology, 49, (2015), pp. 259–265. https://doi.org/10.17222/mit.2012.057.

[4] I. P. Trochun. Internal forces and deformations during welding. State Scientific and Technical Publishing House of Machine-Building Literature, Moscow, (1964). (in Russian).

[5] N. L. Thong. Fusion electric welding technology. Volume 1: Theoretical foundations. Hanoi Science and Technology Publishing House, (2007).

[6] N. T. Duong. Determination of temperature distribution during MIG welding in fillet weld joint between two thin plates of carbon steel and stainless steel. In Proceedings of the 13th International Symposium of South East Asian Technical University Consortium, Hanoi University of Science and Technology, (2019), pp. 18–23.

[7] F. A. Damian Kotecki. Stainless steels - Welding guide. Lincoln Electric, (2003).

[8] GSI SLV Duisburg. The Welding Engineer’s Current Knowledge. International Welding Engineer, (2015).

Downloads

Published

How to Cite

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.